News

July 2020

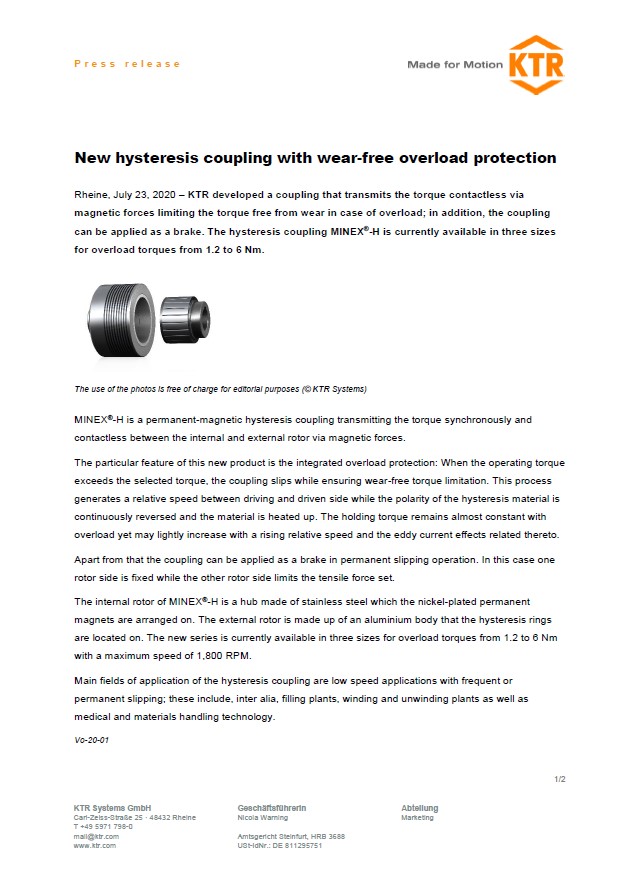

New hysteresis coupling with wear-free overload protection

KTR have developed a coupling that transmits the torque contactless via magnetic forces limiting the torque free from wear in case of overload; in addition, the coupling can be applied as a brake. The hysteresis coupling MINEX®-H is currently available in three sizes for overload torques from 1.2 to 6 Nm.

_____________________________________________________________

December 2018

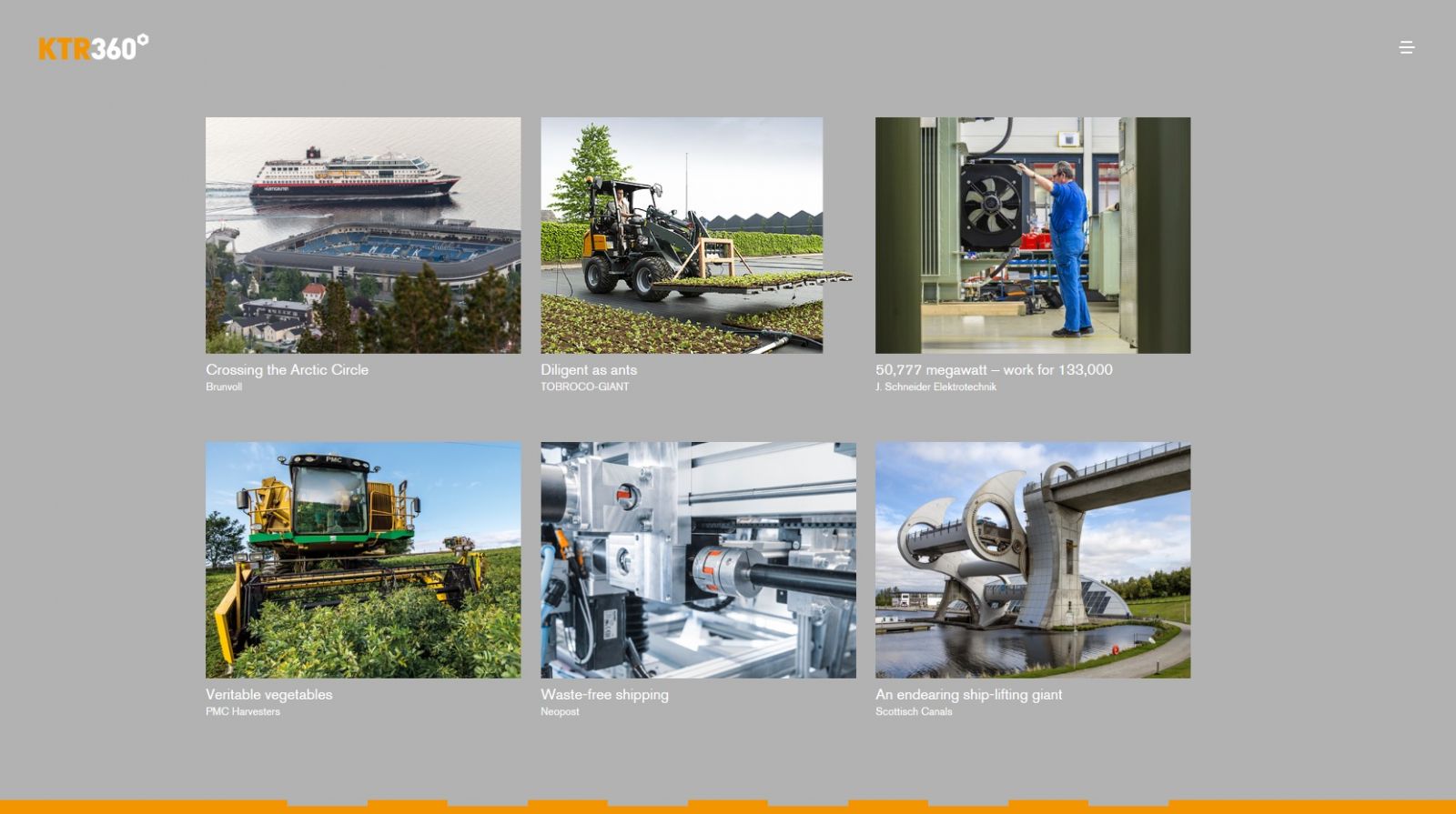

KTR launched a new Online Magazine which is available at www.ktr360.com with immediate effect. The platform tells about prominent applications and projects of the world of KTR focusing on storytelling and moving images.

The KTR360° Online Magazine is the digital counterpart of the annual Yearbook telling both enjoyably and informatively about special applications and projects KTR was involved and engaged in.

KTR360.com focuses on storytelling, picture galleries and moving images and provides a forum to the customers. The online platform is published in German and English and is to be developed to become another content-related platform of the company. The Yearbook will continue to be published as a high-quality print work.

The Online Magazine was launched comprising six articles and is to be regularly supplemented by a new „success story“ from the world of KTR.

_____________________________________________________________The Online Magazine was launched comprising six articles and is to be regularly supplemented by a new „success story“ from the world of KTR.

July 2018

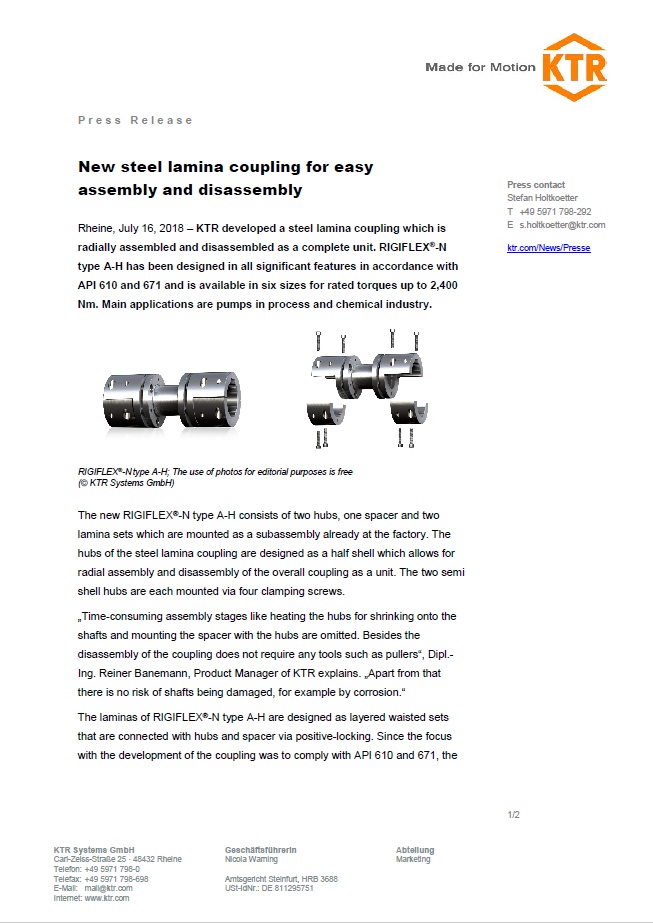

New steel lamina coupling for easy assembly and disassembly

KTR has developed a steel lamina coupling which is radially assembled and disassembled as a complete unit. RIGIFLEX®-N type A-H has been designed in all significant features in accordance with API 610 and 671 and is available in six sizes for rated torques up to 2,400 Nm. Main applications are pumps in process and chemical industry.

_____________________________________________________________

April 2018

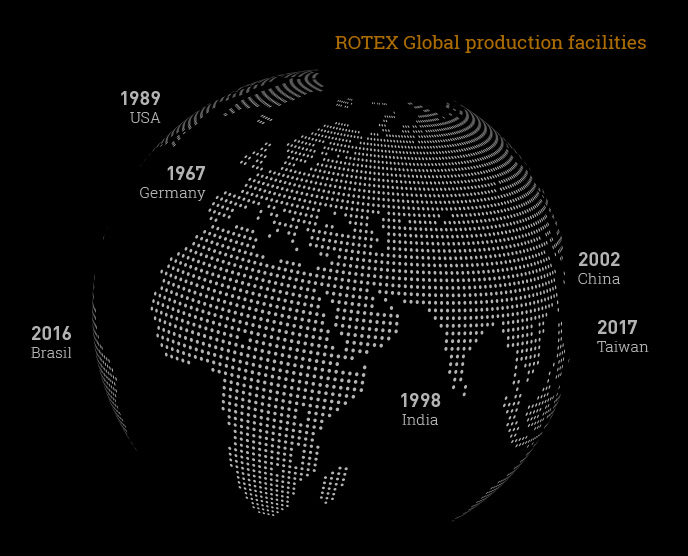

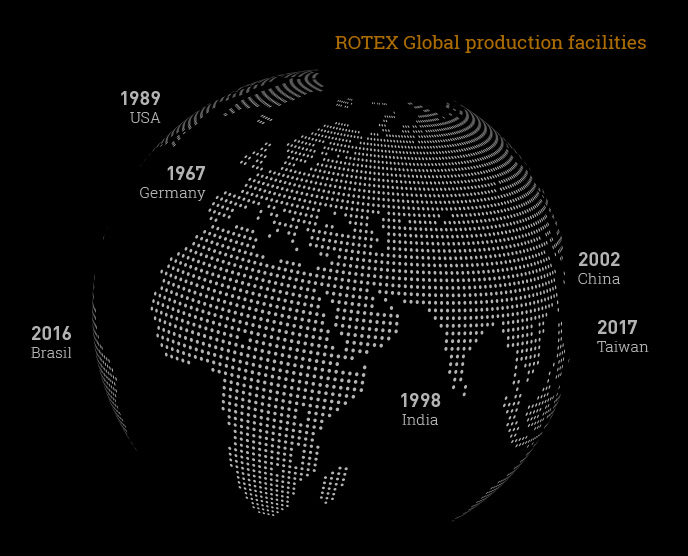

ROTEX turns..

It’s 1967

German TV stations begin transmitting in colour … the

first heart is transplanted in Cape Town … and in space

the first automatic docking manoeuvre takes place between

the two unmanned Soyuz spacecraft Kosmos 186 and

Kosmos 188. Back on Earth in the small German town of

Rheine in Westphalia and largely unnoticed by the global

public, a no less ground-breaking ‘docking’ is performed: two

coupling hubs made of steel join up and encapsulate a flexible

spider made of plastic. The ROTEX is born! The new jaw coupling

was a milestone in the success of the emergent company then

called KTR Kupplungstechnik – today KTR Systems.

first heart is transplanted in Cape Town … and in space

the first automatic docking manoeuvre takes place between

the two unmanned Soyuz spacecraft Kosmos 186 and

Kosmos 188. Back on Earth in the small German town of

Rheine in Westphalia and largely unnoticed by the global

public, a no less ground-breaking ‘docking’ is performed: two

coupling hubs made of steel join up and encapsulate a flexible

spider made of plastic. The ROTEX is born! The new jaw coupling

was a milestone in the success of the emergent company then

called KTR Kupplungstechnik – today KTR Systems.

_____________________________________________________________

February 2018

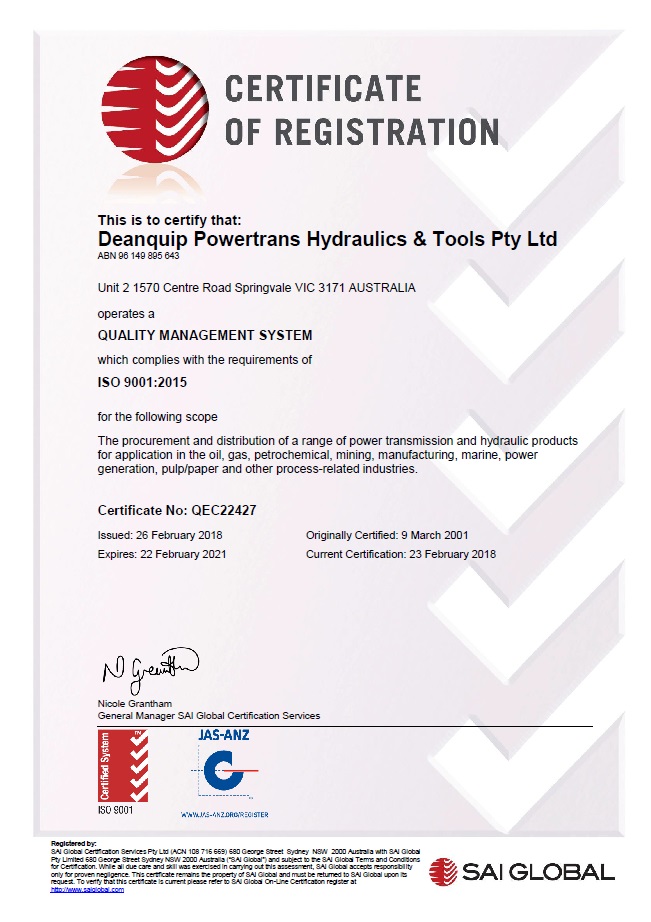

Deanquip Transitions to ISO 9001:2015

Deanquip has proudly communicated its endorsement under the ISO 9001 Quality Management System (QMS), since originally certified in 2001. Not only is this certification a critical requirement in our commercial engagement with many OEM’s, EPC’s and large end users in our market, the benefits of operating a QMS are seen throughout the business in areas including:

Deanquip has proudly communicated its endorsement under the ISO 9001 Quality Management System (QMS), since originally certified in 2001. Not only is this certification a critical requirement in our commercial engagement with many OEM’s, EPC’s and large end users in our market, the benefits of operating a QMS are seen throughout the business in areas including:

• Accuracy of inventory, order processing etc

• Product and service quality

• Efficient processes

• Providing a medium for continuous assessment and improvement

Over the past 12 months, we have been working on our re-certification, and transition to the new ISO 9001:2015 international standards.

This has involved in-depth reviews (and re-writes) of our Quality Management System, including policies, quality procedures, work instructions etc. In February, Deanquip were audited by SAI Global and received re-certification, and importantly the transition to the ISO 9001:2015 standard.

The ISO 9001:2015 standard is constructed around seven quality management principles:

1. Customer focus

2. Leadership

3. Engagement of people

4. Process approach

5. Improvement

6. Evidence-based decision making

7. Relationship management

Risk-based thinking has a very important place in ISO 9001:2015. Organisations are strongly encouraged to use risk analysis in order to decide which challenges may arise in the management of the business processes.

Formal risk analysis, familiar to many organisations via FMEA or HACCP techniques, is now standard for everyone. To emphasise their dominance, the concept of ’risk’ occurs forty-eight times in ISO 9001:2015, compared with only three times in ISO 9001:2008.

As an organisation, we continue to strive by constantly assessing the risk across our processes, and implementing regular improvements to minimise and eliminate these areas of risk.

July 2017

Press release from KTR..

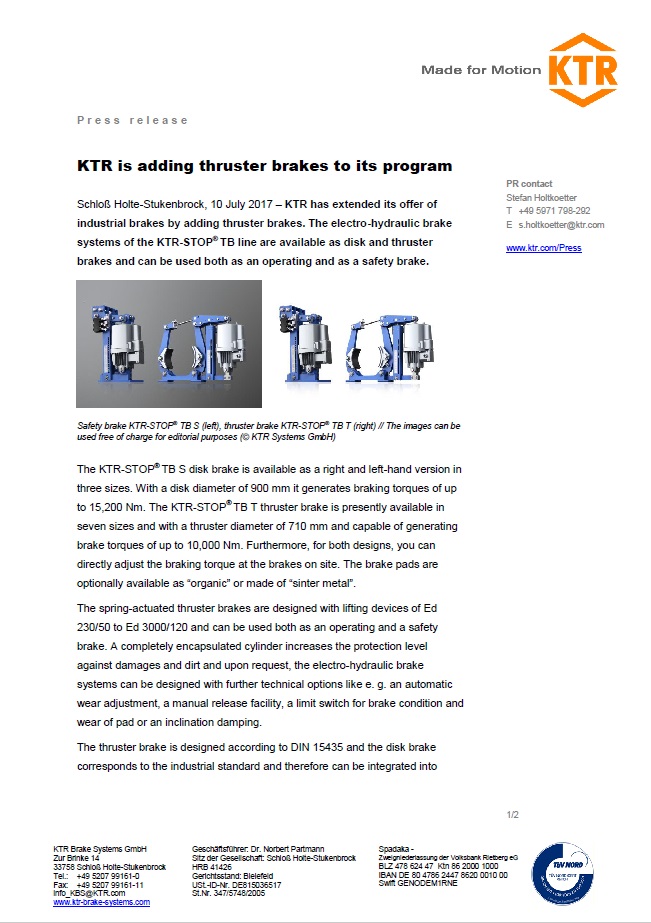

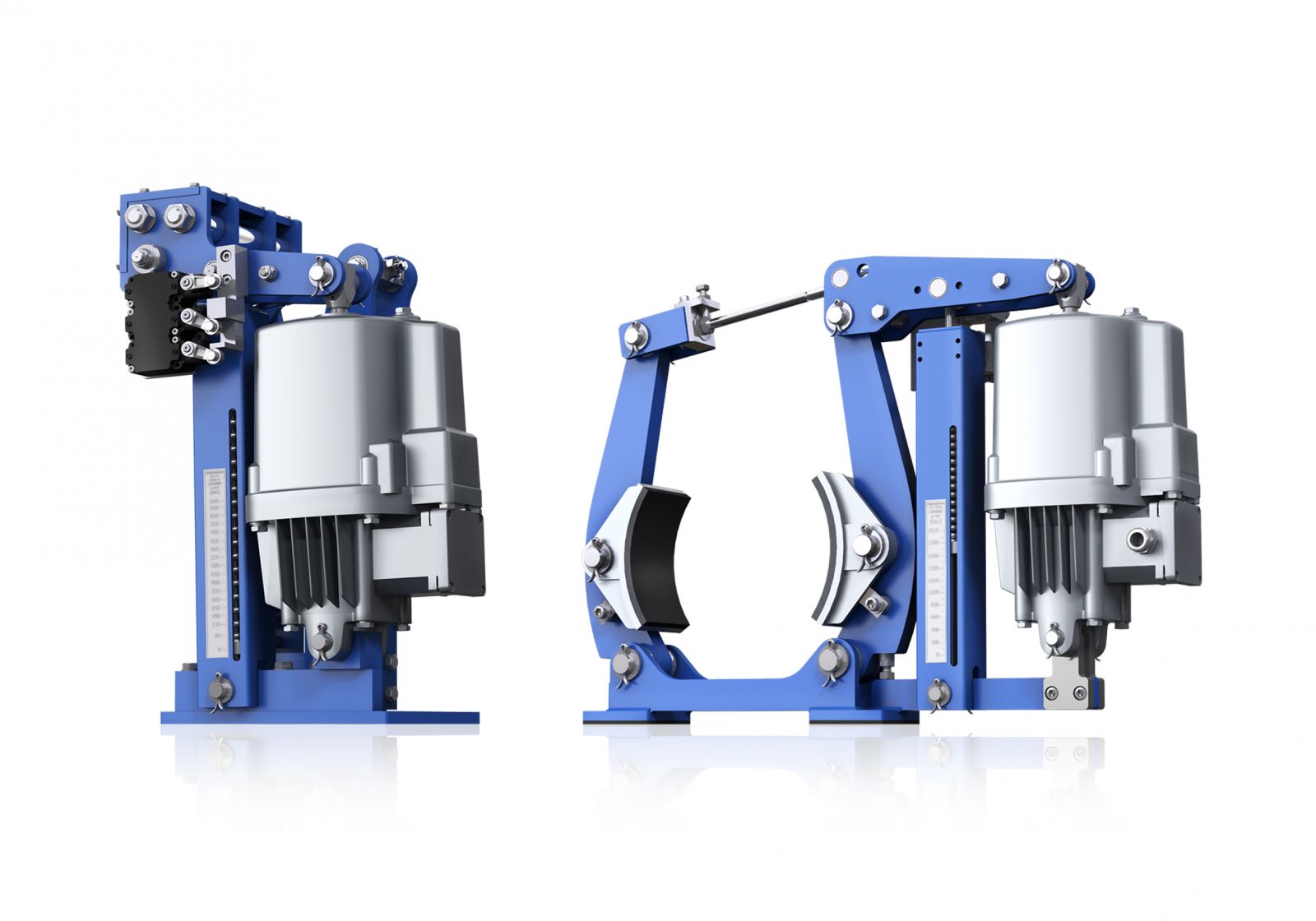

KTR has extended its offer of industrial brakes by adding thruster brakes. The electro-hydraulic brake systems of the KTR-STOP® TB line are available as disk and thruster brakes and can be used both as an operating and as a safety brake.

_____________________________________________________________

April 2017

Press release from KTR..

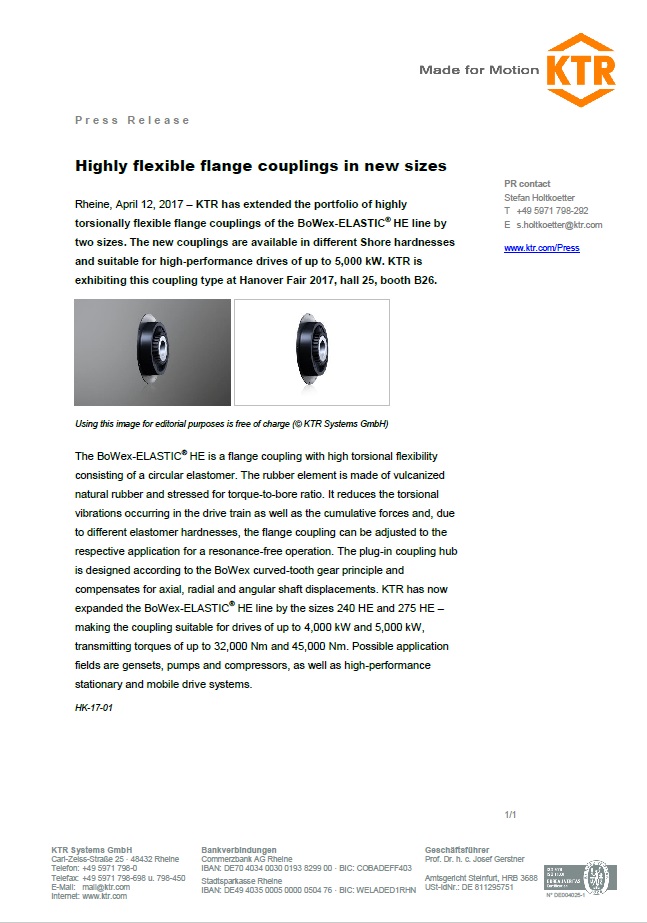

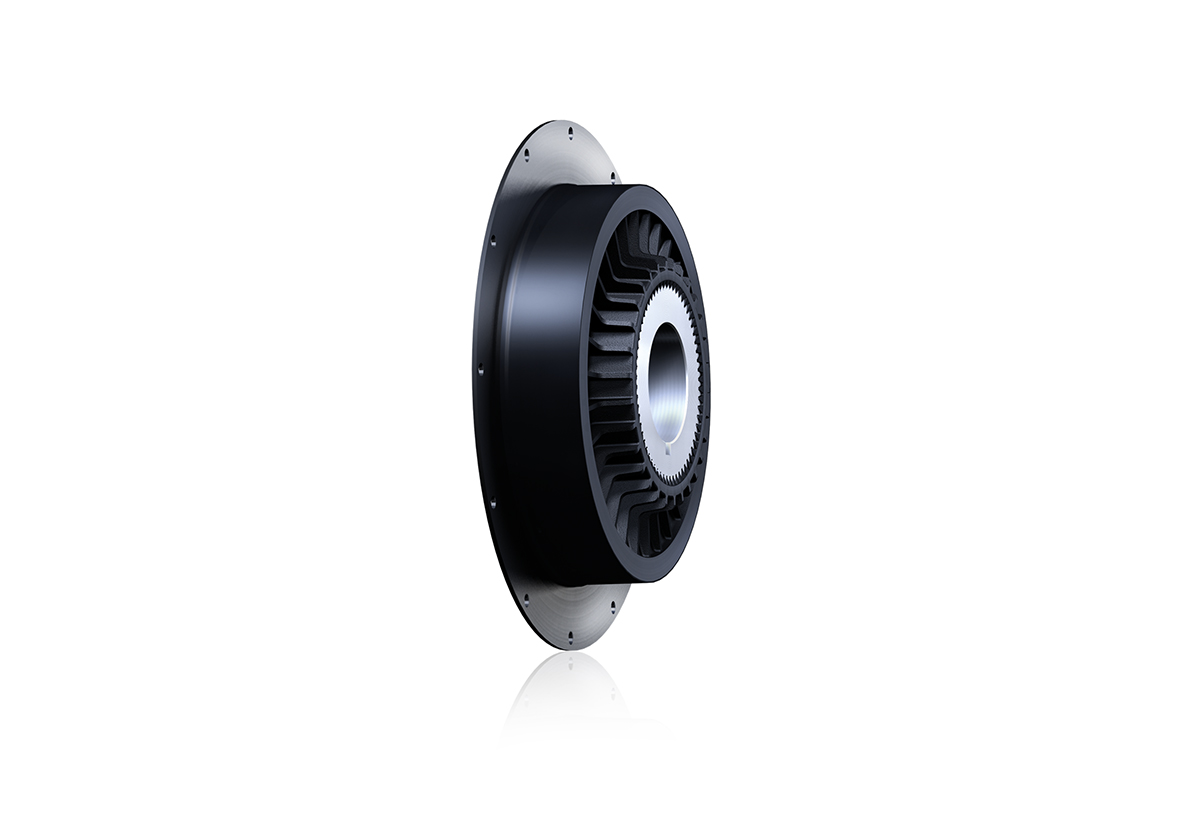

KTR has extended the portfolio of highly torsionally flexible flange couplings of the BoWex-ELASTIC® HE line by two sizes. The new couplings are available in different Shore hardnesses and suitable for high-performance drives of up to 5,000 kW.

_____________________________________________________________

February 2017

Press release from KTR..

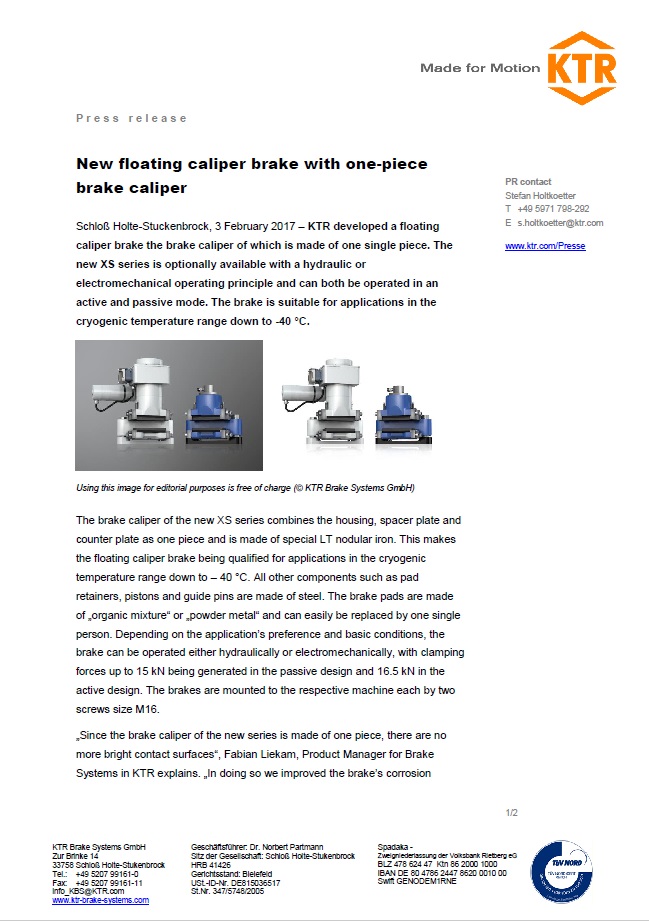

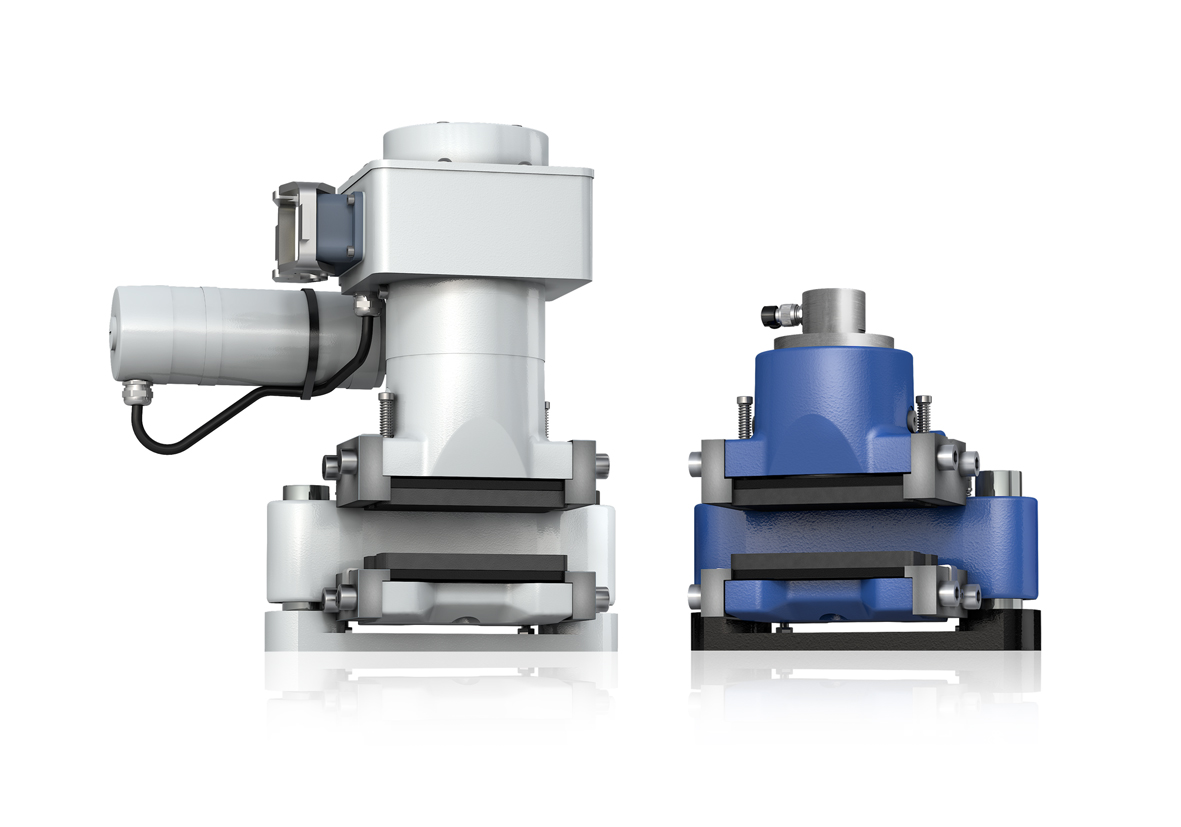

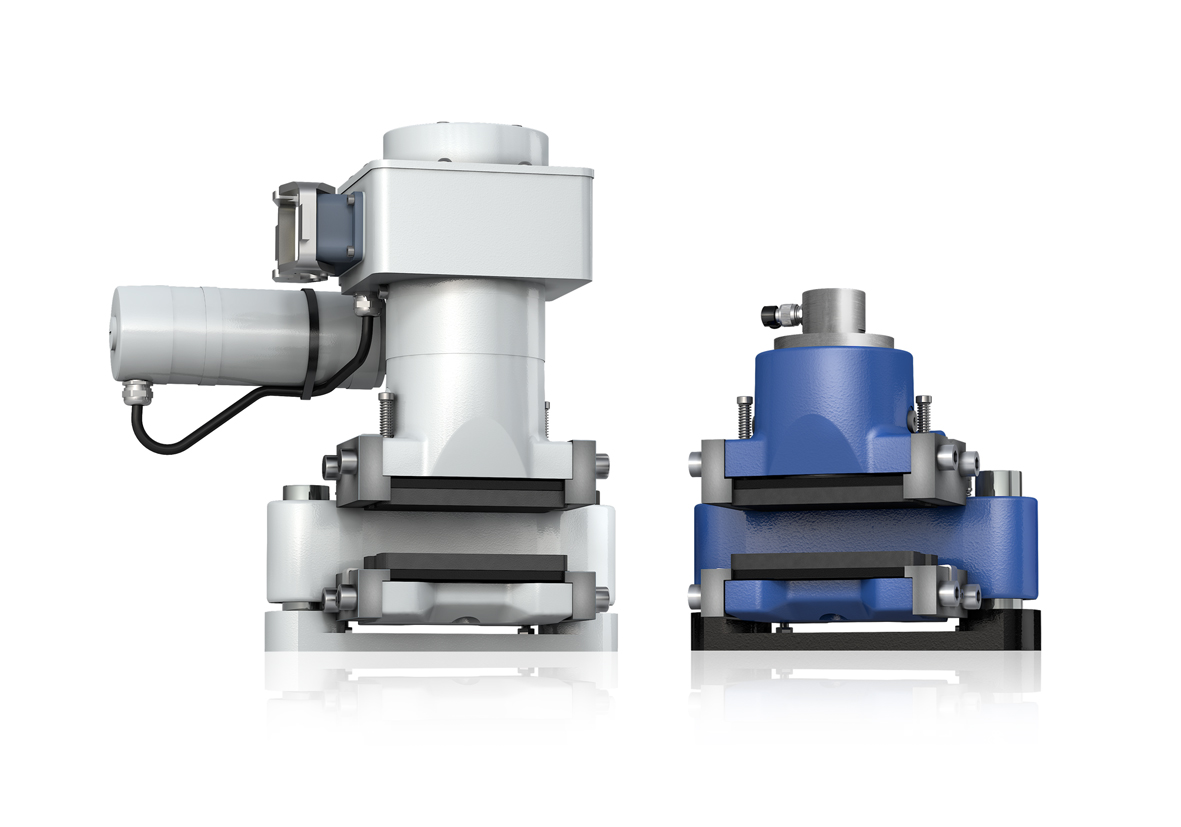

KTR developed a floating caliper brake the brake caliper of which is made of one single piece. The new XS series is optionally available with a hydraulic or electromechanical operating principle and can both be operated in an active and passive mode. The brake is suitable for applications in the cryogenic temperature range down to -40 °C.

_____________________________________________________________

November 2016

_____________________________________________________________

August 2016

_____________________________________________________________

_____________________________________________________________

June 2016

• Continuing the expansion - Opening of a new plant in China

The new test bench is provided with an electrical variable-speed drive generating a maximum testing torque of 500,000 Nm via several gears. The torque is measured on the gear output side through a calibrated measuring shaft via DMS technology while the twisting angle is calculated on the drive side through a pulse encoder or a position sensor which is installed directly on the testing sample. The data acquired allow to calculate the torsion spring stiffness. Apart from recording mechanical coupling figures, testing of component strength and service life is performed on the new test bench. In addition positive-locking and frictionally engaged overload systems will be tested and set here.

Download Press release..

KTR developed a floating caliper brake the brake caliper of which is made of one single piece. The new XS series is optionally available with a hydraulic or electromechanical operating principle and can both be operated in an active and passive mode. The brake is suitable for applications in the cryogenic temperature range down to -40 °C.

_____________________________________________________________

November 2016

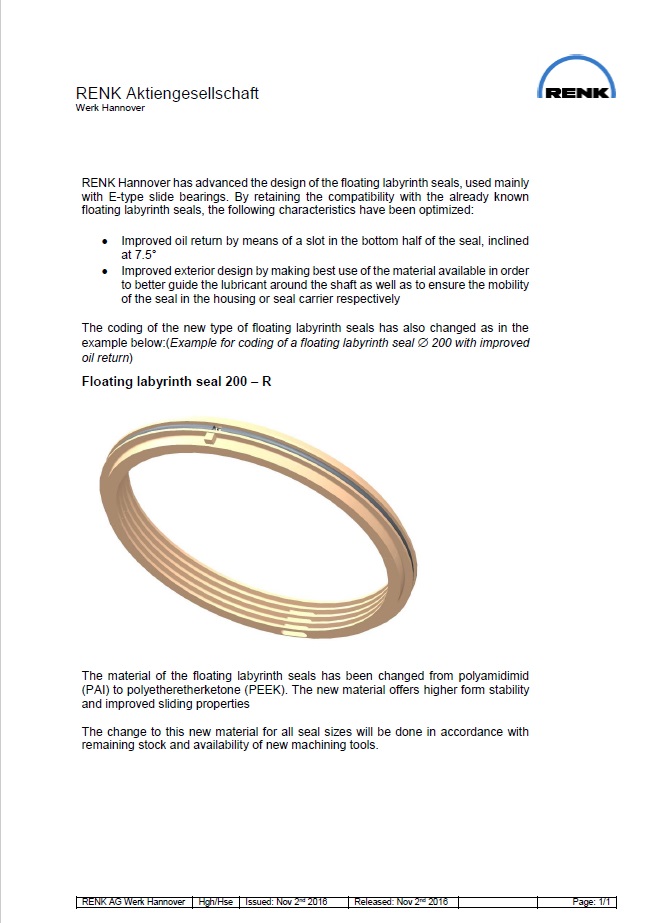

RENK AG Company-News..

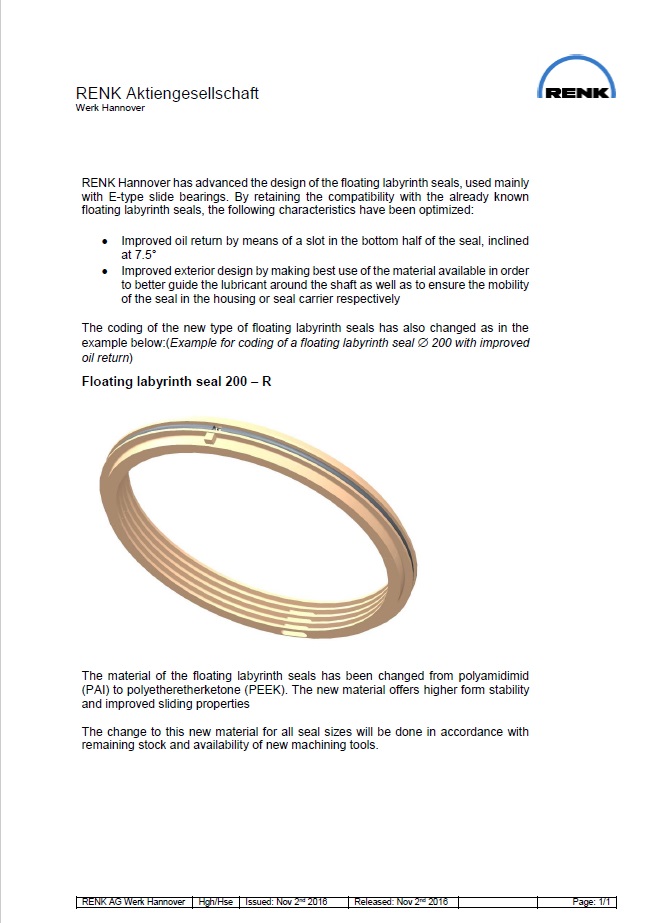

RENK Hannover has advanced the design of the floating labyrinth seals, used mainly with E-type slide bearings.

· Improved oil return

· Improved design via new material properties

RENK Hannover has advanced the design of the floating labyrinth seals, used mainly with E-type slide bearings.

· Improved oil return

· Improved design via new material properties

August 2016

Pump Industry Magazine..

Pump Industry Magazine is Australia’s only dedicated pump magazine.

It is produced by monkey media in co-operation with Pump Industry Australia.

This magazine is targeted at a wide range of pump end-users, communicating useful information about pump applications and in 2015 - Deanquip will run a series of related editorials also, making it your one-stop shop and trusted source for all pump information – whatever industry you are in.

Pump Industry Magazine is both a full-colour printed magazine, produced quarterly and an online portal for all things pumps.

See our August Editorial on Couplings for pumps & turbo-compressors..

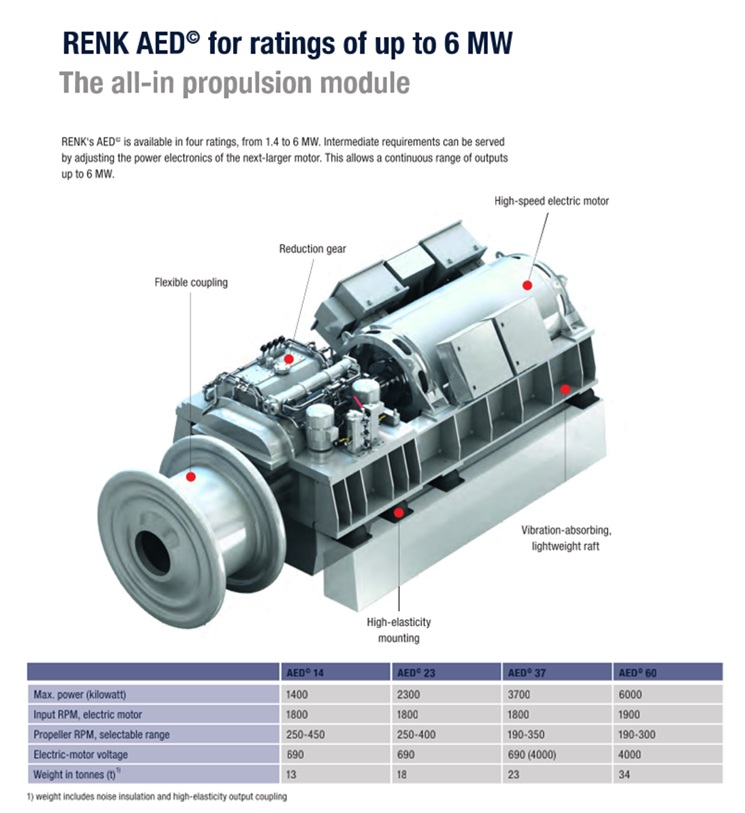

Deanquip Powertrans is pleased to announce that its partner RENK AG has been selected as the supplier for the geared propulsion system for the new Australian Antarctic Division vessel set to replace the Aurora Australis.

The RENK businesses have combined to offer a complete package of main reduction gearboxes, shaft line thrust bearings, Advanced Propeller Clutches (APC) and Advanced Electric Drives (AED).

The RENK AED is a recently developed highly modular technology which integrates the use of a high speed electric motor, high speed coupling, two stage reduction gearbox and a composite, lightweight, highly flexible output coupling. The AED drivetrain is mounted to a single baseplate and fixed to the vessel structure using soft elastic mounts. The purpose of the AED development is to offer a lighter, smaller alternative to direct drive electric motors and to give flexibility to ship operators with a complex speed profile.

The RENK AED offers many advantages over traditional direct drive electric motors as it is typically 40% lighter and occupies 30% less volume than current systems. The AED can be used as the single source of propulsion during low speed, low noise operation (perfect for scientific vessels and mega-yachts) or can be used as additional power to the main diesel engines during icebreaking mode. An advantage of the AED is that it can be used as a generator when operating in diesel engine mode, feeding power back to the vessel to supplement the base load from the Diesel GenSets.

RENK AG are designers and manufacturers of high integrity gear systems and the world leader in gearboxes for naval marine propulsion. Deanquip Powertrans are the exclusive agent in the ANZ region and fully support all RENK businesses with new equipment, aftermarket support and the supply of spare parts.

June 2016

KTR Company-News..

• Continuing the expansion - Opening of a new plant in China

• Change at the top of KTR: Andreas Nauen is new CEO of KTR Group

• KTR started up a new test bench

• Getting faster to the right standard coupling - KTR selection tools provide more speed with the selection of products

Related files

Related files

_____________________________________________________________

March 2016

Press release from KTR..

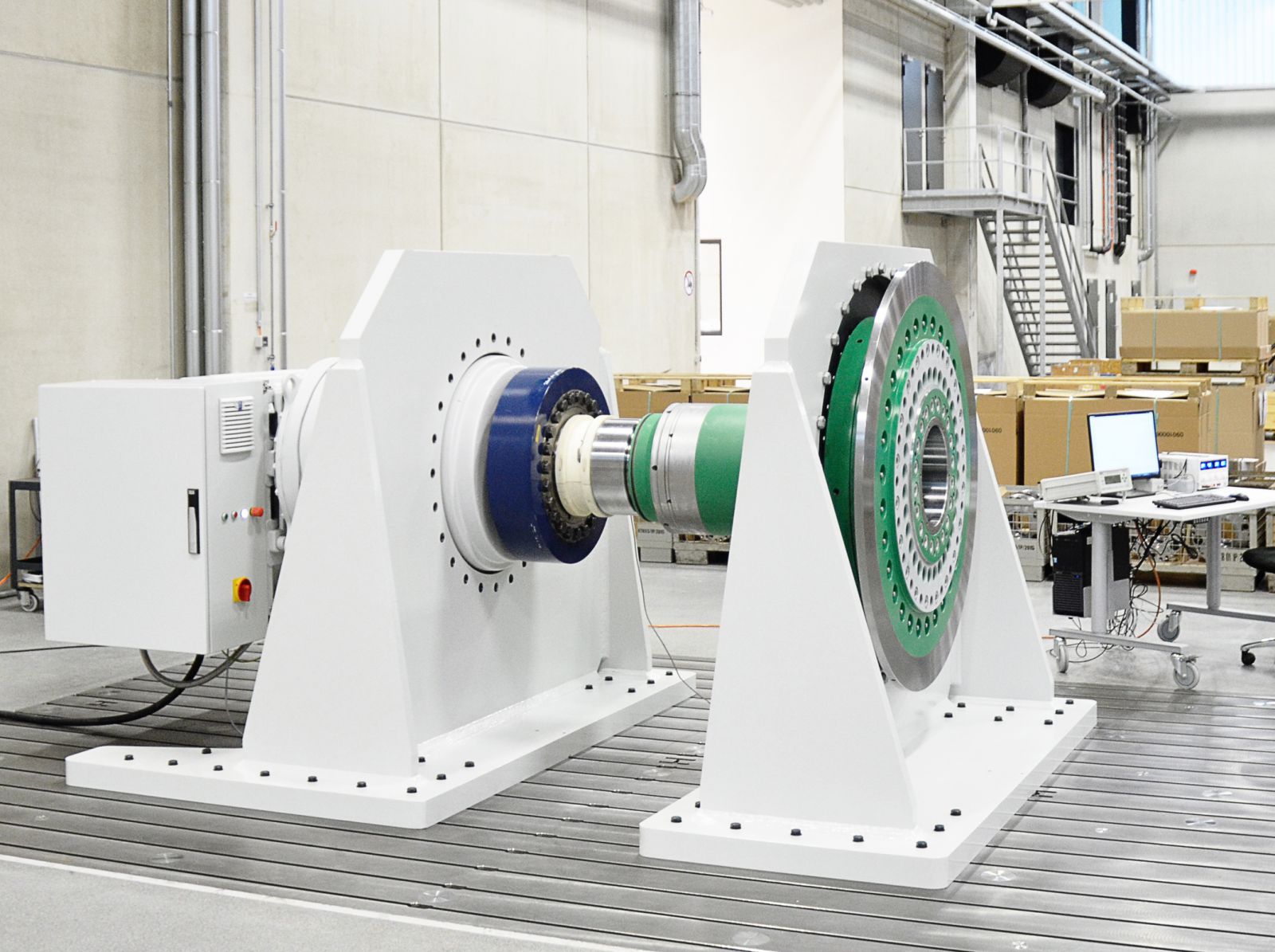

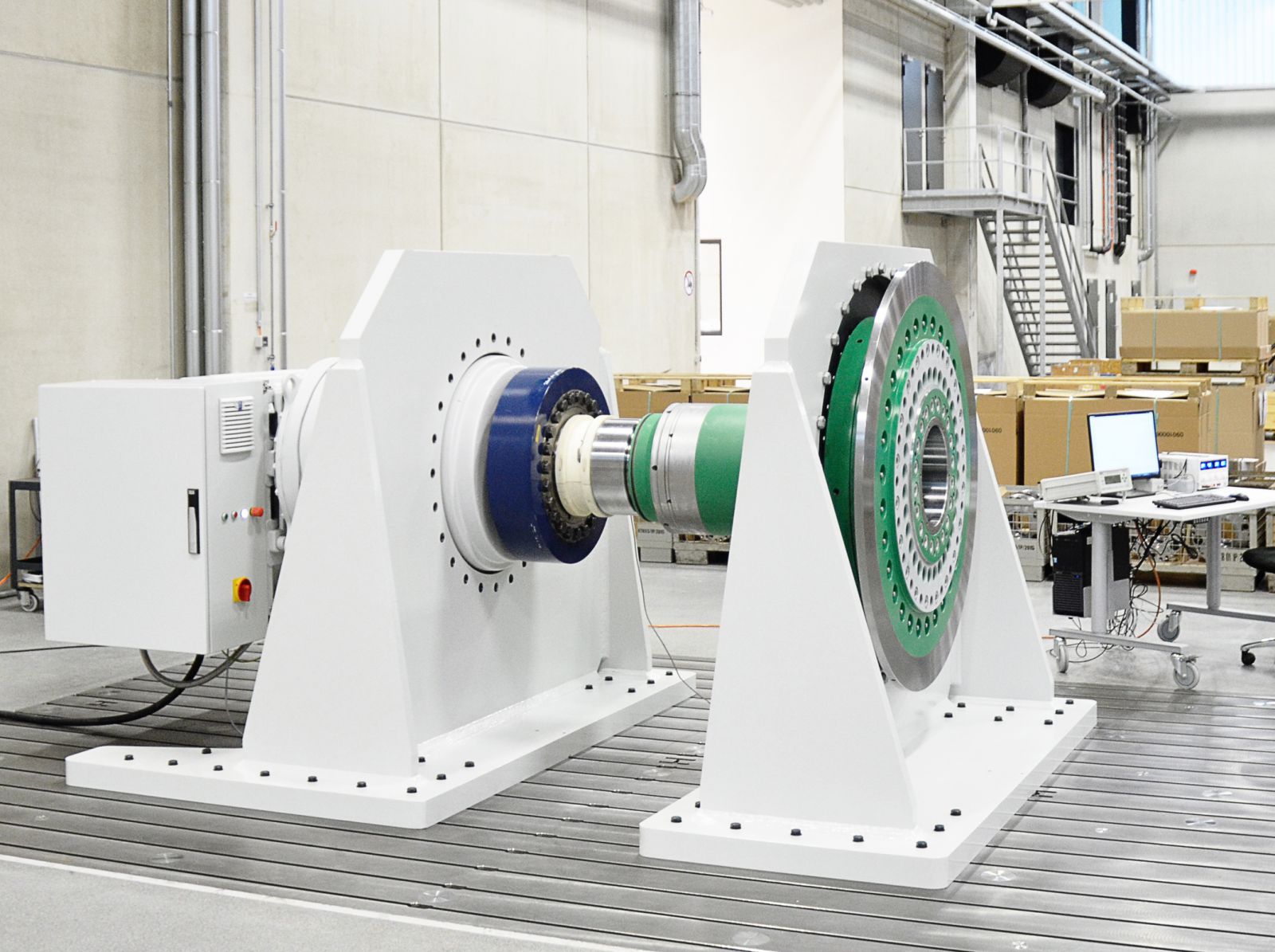

KTR started up a new test bench for large couplings covering a performance range up to 500,000 Nm at the headquarters in Rheine. The test bench allows to calculate mechanical coupling parameters and perform service life testing.

The new test bench is provided with an electrical variable-speed drive generating a maximum testing torque of 500,000 Nm via several gears. The torque is measured on the gear output side through a calibrated measuring shaft via DMS technology while the twisting angle is calculated on the drive side through a pulse encoder or a position sensor which is installed directly on the testing sample. The data acquired allow to calculate the torsion spring stiffness. Apart from recording mechanical coupling figures, testing of component strength and service life is performed on the new test bench. In addition positive-locking and frictionally engaged overload systems will be tested and set here.

Download Press release..

_____________________________________________________________

February 2016

February 2016

Pump Industry Magazine..

Pump Industry Magazine is Australia’s only dedicated pump magazine.

It is produced by monkey media in co-operation with Pump Industry Australia.

This magazine is targeted at a wide range of pump end-users, communicating useful information about pump applications and in 2015 - Deanquip will run a series of related editorials also, making it your one-stop shop and trusted source for all pump information – whatever industry you are in.

Pump Industry Magazine is both a full-colour printed magazine, produced quarterly and an online portal for all things pumps.

See our February Editorial on Improved safety in explosive atmospheres..

_____________________________________________________________

October 2015

Press release from KTR..

_____________________________________________________________

October 2015

Press release from KTR..

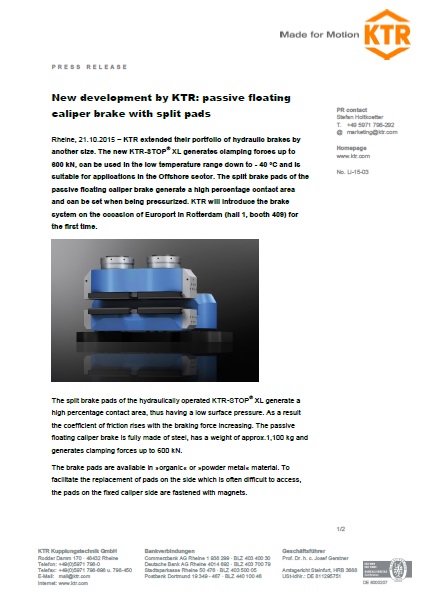

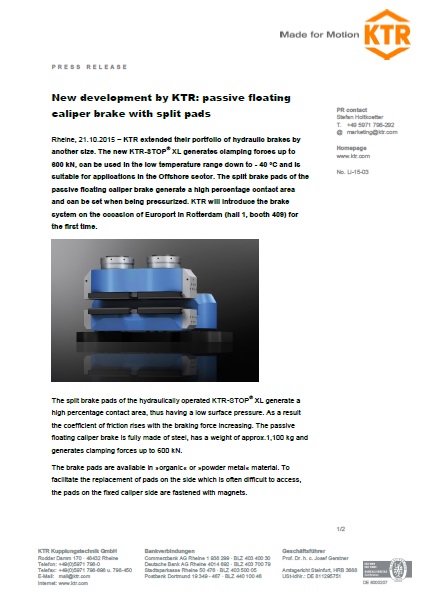

KTR extended their portfolio of hydraulic brakes by another size. The new KTR-STOP® XL generates clamping forces up to 600 kN, can be used in the low temperature range down to - 40 °C and is suitable for applications in the Offshore sector.

The split brake pads of the passive floating caliper brake generate a high percentage contact area and can be set when being pressurized.

The split brake pads of the passive floating caliper brake generate a high percentage contact area and can be set when being pressurized.

_____________________________________________________________