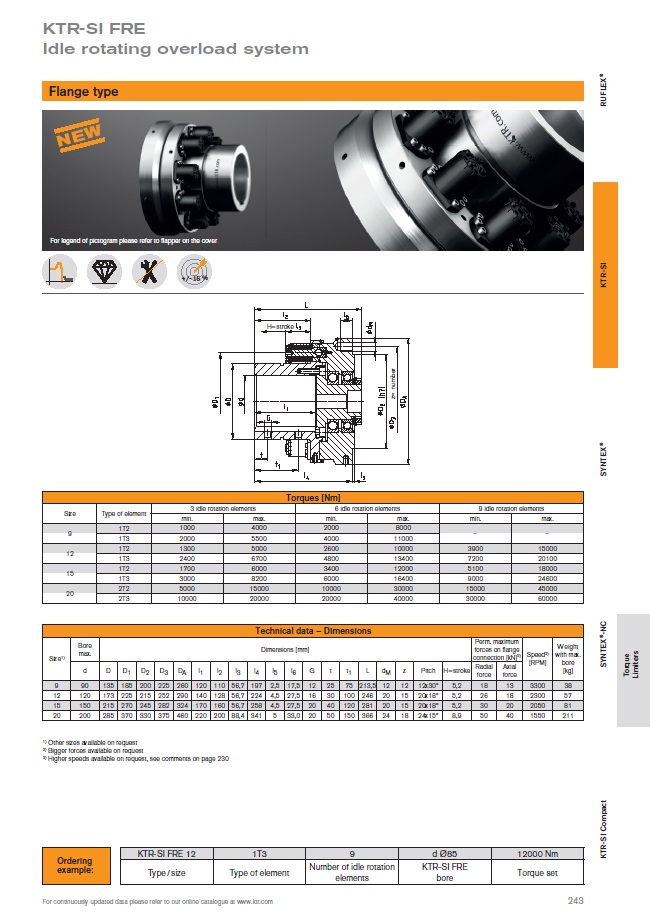

KTR-SI FRE flange type

• Idle-rotation overload system (load-separating)

• High repeating accuracy

• Flange design for the mounting of pulleys or sprockets

• Combination with ROTEX®, GEARex® or RADEX®-N for shaft-to-shaft connections

• The intelligent further development to the shear pin coupling and hydraulic overload systems

• Setting range to 60,000 Nm (higher torques on request)

Description

The core of the overload system is formed by the idle rotation elements. In case of overload they uncouple the driving and driven side while protecting the drive train from damages. After eliminating the overload, the rotation segments are manually re-engaged so that the drive is released again.

Additional Information

Typical applications are, as an example, shredders (recycling), mills (steel industry), extruder drives, test bench technology as well as general heavy-duty drives.

Setting the release torque

In order to set the coupling to the requested release torque, a defined pre-stress is generated on the disk springs in each idle rotation element via the setting nut. The number of elements varies depending on the release torque demanded. If requested, the coupling can be pre-set by the manufacturer. It is also possible to adapt the coupling while in place.

Re-engaging of idle rotation elements

After eliminating the overload driving and driven side are aligned to each other. By means of a plastic hammer or a lever the rotation segments are re-engaged manually while the re-engagement can clearly be heard. Now the overload coupling is ready for operation again.