EVOLASTIC® E/EP

Individual elastomer version for a wide range of applications.

The coupling type E/EP is a highly flexible individual element for versatile application in frequency-controlled and I. C.-engine drives. Subject to its torsionally soft property it serves for insulating vibrations and acoustics in the drive train.

In addition to transmitting the torque the coupling compensates for axial, radial and angular misalignment while absorbing overload flexibly.

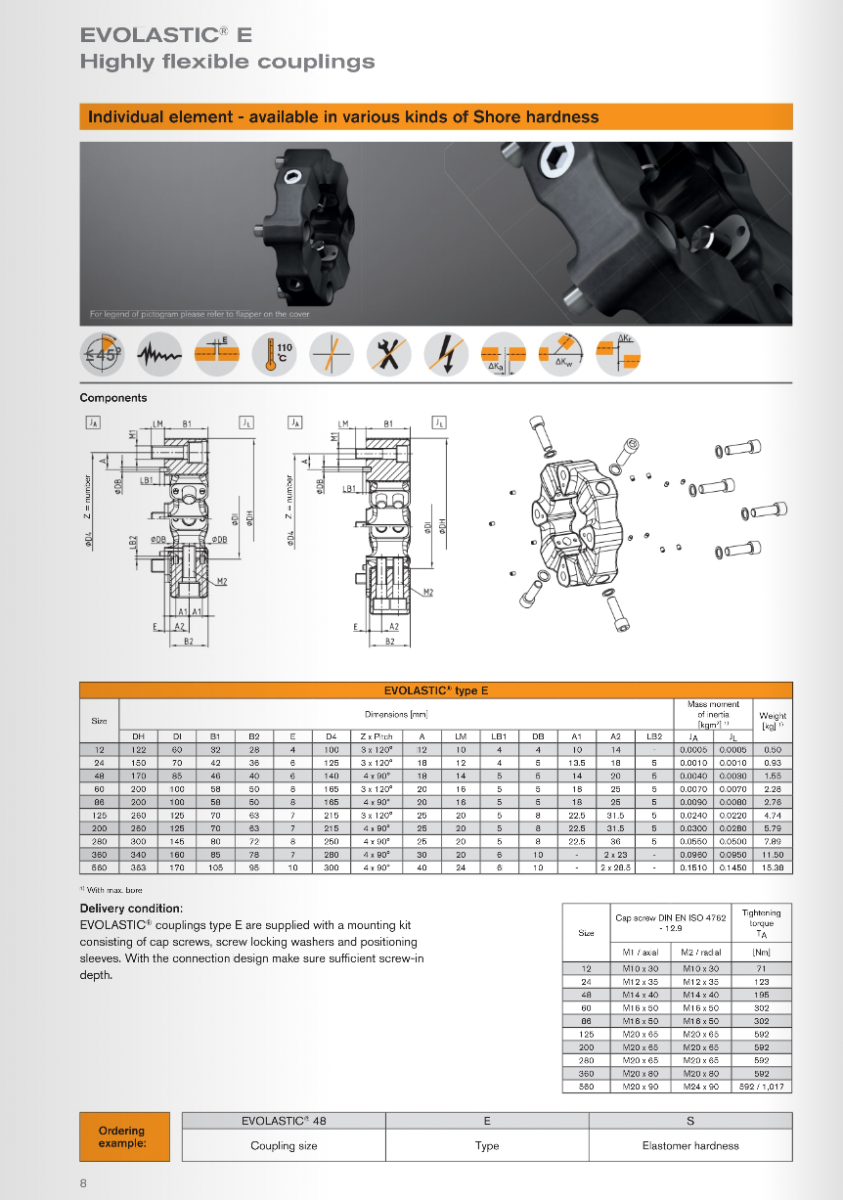

Type E can be screwed in axially and is available in ten sizes.

Type EP can be plugged in axially and is available in seven sizes.

Both types are available in two materials - NR and on request EPDM.

The maximum operating temperature of the element is 90 °C (NR) resp. 110 °C (EPDM).

EVOLASTIC couplings type E are supplied with a mounting kit consisting of cylinder head screws, locking washers and positioning sleeves.

EVOLASTIC couplings type EP are supplied with a mounting kit consisting of cylinder head screws, locking washers, socket pins and positioning sleeves.

Features

• Highly flexible coupling

• Versatile application in mechanical and plant engineering

• Damping torsional vibrations

• Maintenance-free subject to material combination elastomer/steel

• Available in various kinds of Shore hardness SN and MN

• Elastomer materials NR and on request EPDM

• Max. circumferential speed vmax=56 m/s

• Available as axial plug-in and screw-in versions

Additional Information

The key component of the series is a vulcanised, circularly closed elastomer element made of natural rubber (WN, SN, MN, up to 90 °C) or for higher temperatures made of synthetical EPDM material (WE, SE, ME, up to 110 °C).

The different kinds of rubber hardness cover one application and torque range per size.

The designing principle ensures a precise prestress in the elastomer.